About Us

About SF Fasteners

We redefine excellence in the standard fastener industry by merging precision engineering with unwavering commitment to client success. As a global leader, we deliver solutions that empower enterprises to thrive in demanding environments while adhering to the highest international benchmarks.

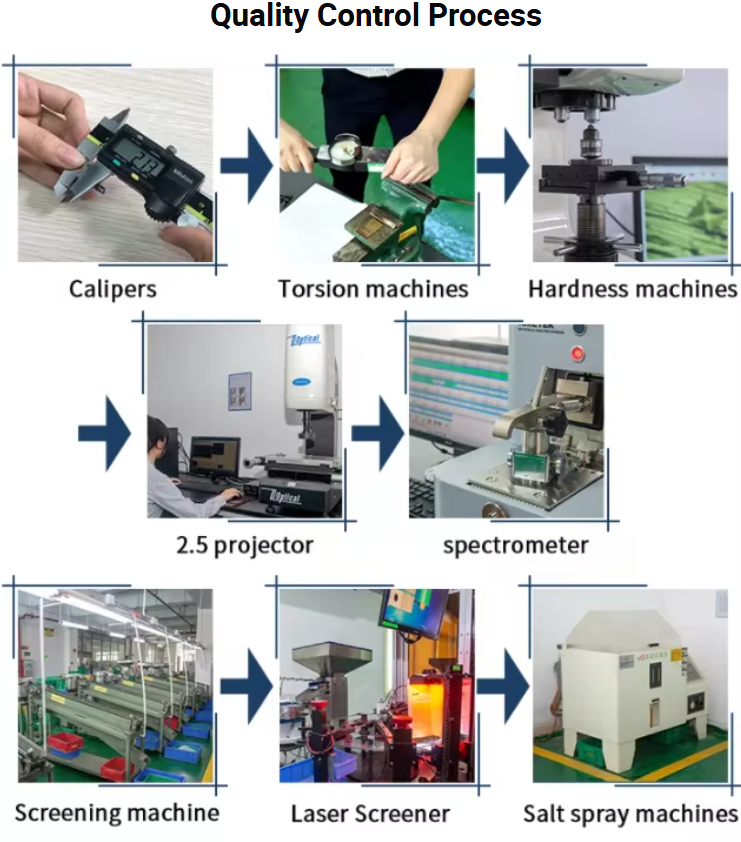

Uncompromising Quality & Reliability

Our foundation is built on precision manufacturing and globally recognized certifications, including ISO 9001 and TUV/CE. Equipped automated production lines, every fastener undergoes rigorous testing—from tensile strength assessments to salt-spray corrosion resistance trials—ensuring compliance with ASTM, DIN, and ASME standards.

Client-Centric Partnerships

Your challenges are our blueprint for innovation. Through quarterly client feedback audits, we’ve refined our Just-In-Time delivery networks to achieve 99.1% on-time shipments across 50+ countries.

Production Process

Wire Drawing

The process begins with steel wire rods of larger diameter. The rods are drawn through a series of progressively smaller dies to reduce the wire to the precise diameter required for the screw being manufactured. This cold-working process also increases the wire’s tensile strength and surface finish.

Cold Heading

The drawn wire is cut to length and transferred to a cold heading machine. Under high pressure, the wire slug is struck by dies to form the screw’s basic shape—including the head and blank body. This is a high-speed, precision forging process that shapes the metal without heating it.

Thread Rolling

The blank screw is fed between two or three hardened threaded dies. Under immense pressure, the dies displace the screw’s surface metal to form precise, strong threads. This rolling process compresses the grain structure, making the threads stronger than if they were cut.

Heat Treatment

For screws requiring specific strength grades, they undergo heat treatment. This typically involves quenching (rapid cooling from high temperature to increase hardness) followed by tempering (reheating to a lower temperature to reduce brittleness and achieve the desired balance of strength and ductility).

Surface Finishing

This step provides corrosion resistance and aesthetic appearance. Common finishes include:

Electroplating: Zinc, nickel, or chrome plating via electrochemical deposition.

Hot-Dip Galvanizing: Dipping in molten zinc for a thick, durable coating.

Phosphating/Oxiding: Creating a corrosion-resistant layer for painting or oil retention.

Quality Inspection & Packaging

Screws undergo rigorous checks such as:

Dimensional inspection using gauges and optical comparators.

Mechanical testing (hardness, tensile strength).

Coating thickness and salt spray tests.

Finally, screws are counted, weighed, and packaged in boxes, bags, or drums with clear labeling.